We support you

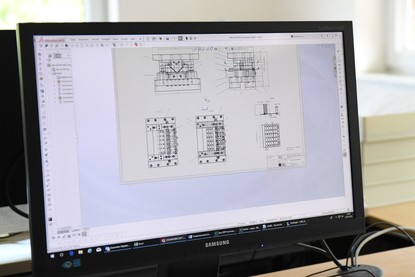

from the drawing to the finished productApart from production and distribution of its standard ranges, VORMANN offers the production of customised products according to customers’ specifications, such as hinges from drawings. To achieve this, we have not only acquired the necessary expert knowledge in more than 150 years of corporate history, but also the appropriate machinery and equipment. In addition to our own engineering department, we have an in-house tool making shop, which enables us to respond quickly and flexibly to our customers’ wishes as well as to any problems that may occur in production. One of our guiding principles is that we always strive to fully satisfy our customers’ requirements regarding their products as well as those of our own quality standards. When our customers have placed an order with us to manufacture their special products, we produce the necessary tools and keep them in perfect condition and ready to use in production throughout their entire service life. Every product we make is thoroughly examined by our quality assurance team from the first outturn sample coming from a new tool right up to series production. Our quality assurance team is responsible for developing every new product to readiness for series production in close cooperation with the relevant departments of our customers. Series production start-up only takes place after the customer has approved the product.

With our modern machinery, including automatic punching presses ranging from 450 to 4000 kN, hydraulic presses from 250 kN to 2000 kN as well as other automation and robot technologies, we can carry out all manufacturing processes at our own facility. We process mainly strip stock in many different grades of steel, stainless steel and brass. We apply the surface finish in-house with several barrel finishing machines and one powder coating line. Thanks to our long-standing business relations with reliable suppliers, we are of course also in a position to apply any other technical surface finish desired by our customers.

In production, we rely on the “Made in Germany” quality seal and have our entire production process monitored by TÜV Nord, a recognized testing agency. Regular audits ensure consistent high quality standards, certified according to EN ISO 9001:2015.